About Automatic CNC Laser Cutting Machine

An advanced piece of machinery known as an automatic CNC (Computer Numerical Control) laser cutting machine makes precise and automatic cuts in a variety of materials using laser technology. It combines laser cutting's versatility and accuracy with the accuracy and speed of CNC control.

An automatic CNC laser cutting device has the following salient qualities and characteristics:

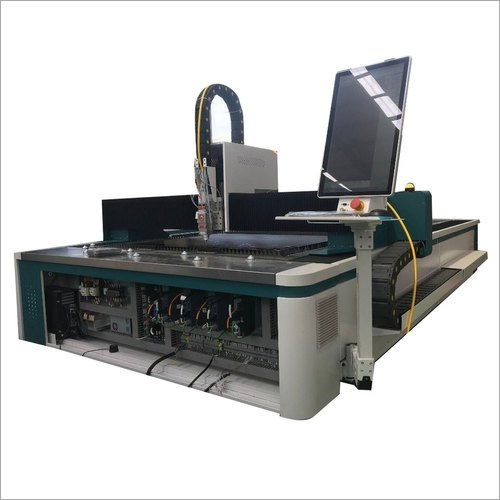

1. CNC Control System: The machine has a CNC control system that translates digital design files into exact cutting instructions. The laser head and other machine parts are moved in unison by the control system to create the desired cutting pathways.

2. High-powered laser sources, including CO2 or fibre lasers, are used by the laser cutting machine. The specific material being cut and the intended cutting skills determine which laser source should be used. While fibre lasers are frequently used for metals like steel, aluminium, and stainless steel, CO2 lasers are best suited for non-metallic materials including wood, acrylic, and plastics.

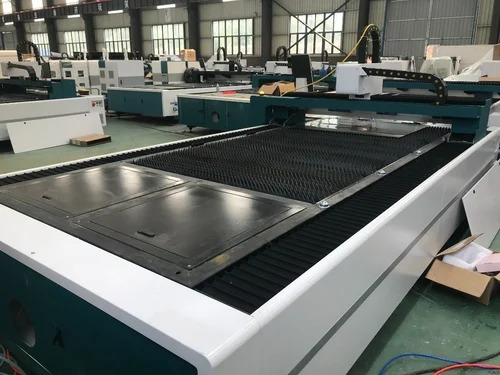

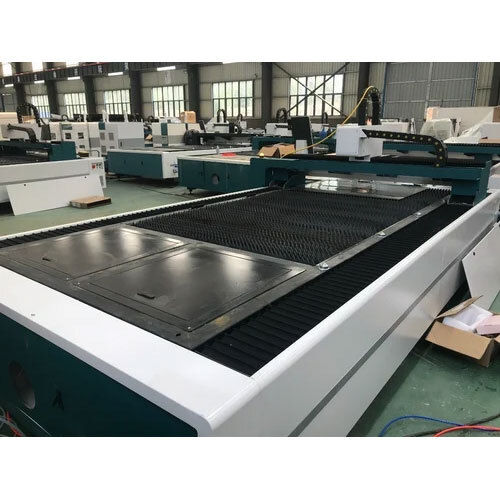

3. Cutting Bed: The material to be cut is put on a flat surface called the cutting bed. Usually, it has a mechanism that keeps the material firmly in position while it is being cut. For continuous manufacturing, the cutting bed may also include features like automatic material feeding or unloading devices.

4. The focusing lens and other optics that direct and focus the laser beam onto the material are found in the laser head. The depth and quality of the cutting are determined by the focal length and positioning of the lens. To improve cutting performance, some machines may have an automatic focal length adjustment option.

5. Automatic CNC laser cutting machines have safety features built in to safeguard operators and guarantee safe operation. These characteristics can protect against exposure to the laser beam by using safety enclosures, interlocks, and laser safety systems.

6. Software Compatibility: A variety of design software applications are compatible with CNC laser cutting machines. DXF, DWG, AI, and SVG are frequently used file types when cutting materials with a laser. These files are imported by the machine's control system so that the cutting paths can be executed precisely.

7. Automation and integration: For effective and continuous manufacturing processes, automatic CNC laser cutting machines can be integrated into production lines or automated systems. They can have features like robotic loading and unloading, automatic material handling, and in-line quality control systems.

8. Flexibility: CNC laser cutting machines are flexible in that they can cut a variety of materials and thicknesses. They are appropriate for a variety of industries, including manufacturing, signage, automotive, aerospace, and more because they can produce complicated and precise cuts, including straight lines, curves, and complex shapes.

It's crucial to keep in mind that exact features, cutting capacities, and capabilities may differ based on the CNC laser cutting machine's brand and model. It is advised to speak with the manufacturer or supplier before considering the purchase or use of an automatic CNC laser cutting machine to make sure the device will fit your unique needs.

Specification

|

Cutting Method

|

Laser

|

|

Material

|

Mild Steel

|

|

Max Cutting Speed

|

3000 mm/min

|

|

Max Cutting Thickness

|

20 mm

|

|

Automation Grade

|

Automatic

|

|

Country of Origin

|

Made in India

|

|

Max Cutting Width

|

3000 mm

|

|

Voltage

|

230 V

|

|

Frequency

|

50 Hz

|

|

Phase

|

Single Phase

|

|

Power

|

1.5 kW

|

FAQ

1. What is a CNC laser cutting machine that is automatic?

Ans - An automated device that uses lasers to cut materials including metal, plastic, and wood is known as a CNC laser cutting machine. It is often controlled by computer numerical control (CNC) software, enabling the machine to quickly and accurately cut parts.

2. What kinds of materials can an automatic CNC laser cutting machine cut?

Ans - Aluminium, brass, copper, fibreglass, stone, wood, and other materials can all be sliced using an automatic CNC laser cutting machine.

3. Are automatic CNC laser cutting machines accurate?

Ans - Depending on the type of material being cut, an automatic CNC laser cutting machine's accuracy is often highly exact. Up to a nano level, the cut precision is typically very reliable.

4. What shapes are capable of being cut by automatic CNC laser cutting machines?

Ans - Straight lines, circles, squares, and other shapes and sizes can be precisely sliced with an automatic CNC laser cutting machine.

5. Which sectors of the economy are benefited by automatic CNC laser cutting machines?

Ans - Many different industries, including aerospace, automotive, medical, electronics, and jewellery, use automatic CNC laser cutting machines. They are also common tools for prototyping software.

Technical Details

Send Inquiry

Send Inquiry