- Home Page

- Company Profile

-

Our Products

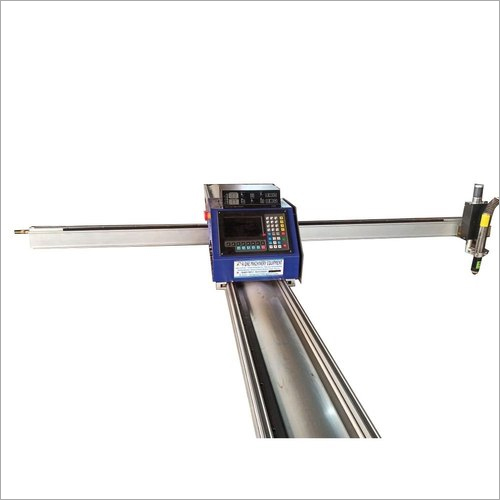

- CNC Plasma Cutting Machine

- Laser Cutting Services

- CNC Machine Spare Parts

- Stepper Motor

- Plasma Torch Height Controller

- CNC Software

- CNC Machine Controller

- Hypertherm Plasma Consumables

- CNC Plasma Cutting Torch Head

- CNC Laser Cutting Machine

- Inverter Plasma Cutting Machine

- Stepper Motor Drives

- Fiber Laser Cutting Machine

- Plasma Cutter

- Laser Cutting Machine

- Cnc Profile Cutting Machine

- Plasma Cutting Electrode

- Hypertherm Plasma Cutter

- Cnc Cutting Machine

- Hydraulic Press Brake Machine

- Laser Marking Machine

- Cnc Laser With Tube Cutting Machine

- Drill Machine

- Air Plasma Cutting Machine

- Laser Machine Parts

- Cnc Gas Cutting Machine

- Contact Us

Call us now07971549139